SDi’s Sanitary Flange Sensors

The CS10, CS40, CS41, CS42, CS51 sensors are TIG welded to blind flanges of customer specified size. The sensors can then be inserted into standard tee fittings in sanitary systems using Ladish or Tri-Clover fittings. TC elements are potted in the body itself. Leads are 10′ standard. Process connections are customer specified size sanitary flanges. The insertion depth can be modified on request to obtain proper positioning i

READ MORE July 30th, 2020

July 30th, 2020 admin

admin

-

Best Practices & Methods

Best Practices & Methods

-

0 Comments

0 Comments

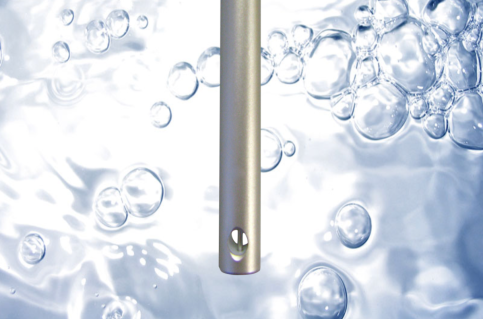

Bubbles, the underestimated enemy.

Bubbles on the surface of the electrodes are a common, but little appreciated problem. Trapped bubbles cause the conductivity readings to be unstable, and lower than expected. Click the link below to find out how to quickly check for bubbles, their sources, and ways to limit their impact below. Explore more on this topic by clicking the link below and contact the factory if you have any questions.

June 8th, 2020

June 8th, 2020 admin

admin

-

Best Practices & Methods

Best Practices & Methods

-

0 Comments

0 Comments

Sensor cleaning

Dirty or contaminated electrodes cause the conductivity readings to fall off with time. Producing lower than expected readings. Click on the link below for a free copy of our cleaning procedure.

READ MORE April 12th, 2020

April 12th, 2020 admin

admin

-

Best Practices & Methods

Best Practices & Methods

-

0 Comments

0 Comments

Sensor Selection Guide

Each type of conductivity sensor has certain applications for which it is best suited and some of that is addressed in the sensor selection guide below. Standard sensors are manufactured from 316L stainless steel electrodes. In most cases the electrodes are available in other materials upon request including; titanium, Monel, and Hastelloy-C. Standard insulators are made from FDA approved teflon. Other insulator materials are

READ MORE April 1st, 2020

April 1st, 2020 admin

admin

-

Best Practices & Methods

Best Practices & Methods

-

0 Comments

0 Comments