pH

Our spec sheets on our pH sensors do not begin to list all the special electrodes because there are, conservatively, dozens of kinds that could be specified. Antimony, double junctions with special front fills, highly ruggedized glass, flat bulbs, gold ORP, and many, many more can be obtained for the asking.

PHS-A pH & ORP Sensor

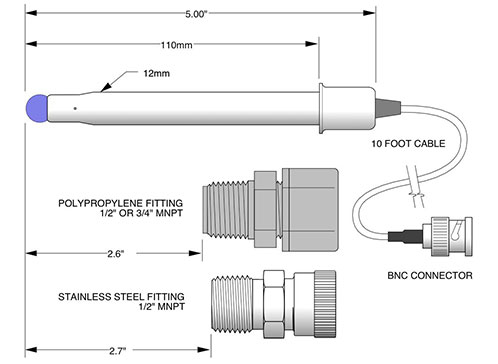

- Measuring cartridge can be removed by hand for fast and easy service

- O-ring seals used on all versions for high on-stream reliability

- Optional stainless fitting allows high pressure operation

This arrangement provides the lowest cost, most convenient version of a pH sensor. The measuring cartridge is held in the process line with a simple fitting rather than the large, expensive and often totally unnecessary sensor housings. So, what you see is not only what you get, it’s probably all you need for 90% of your applications.

Application Notes

Wetted materials of construction are epoxy or glass, and polypropylene or optional metals, with o-ring seals of Buna-N or optional EPR. A wide variety of specialized electrodes may be specific, including: ruggedized, high temperature, high pH, sodium resistant, fluoride resistant, low temperature, flat tip, ORP, specific ion and many others. Temperature compensation element can be held in a separate thermowell, or built into the body of the sensor.

Process connections are made via a bored through swage fitting with 1/2″ or 3/4″ NPT threads, or optional weld connection. This fitting can be screwed into a line, a tank, or it can be turned around and connected to a standpipe for use in a submersion configuration. The standard cable length of ten feet allows connection to the analyzer without needing additional cable in many cases. Simple solutions are often the best, and this sensor sets out to prove that.

TEMPERATURE COMPENSATION:

The temperature element is normally a separate item, but it can be furnished inside the electrode on request.

SPECIFICATIONS

MAX. PRESSURE/TEMP. RATINGS:

Depends on electrode selection.

WETTED MATERIALS:

Body – Glass or epoxy or polyethersulfone

Fitting – Polypropylene, optional 316SS

O-Rings – EPR

CONNECTIONS:

Process – Polypropylene 1/2″ or 3/4″ NPT or 316SS

Electrical – BNC connector