Conductivity

Properly understood and applied, conductivity is probably simpler to operate and maintain than any other analytical measurement. Each type of sensor has certain applications for which it is best suited. Most applications decisions involve the sensor more than the instrument. Modern instruments are so featured-packed that they will cover almost any application, but not so the sensors. They are where the measurement system meets the process.

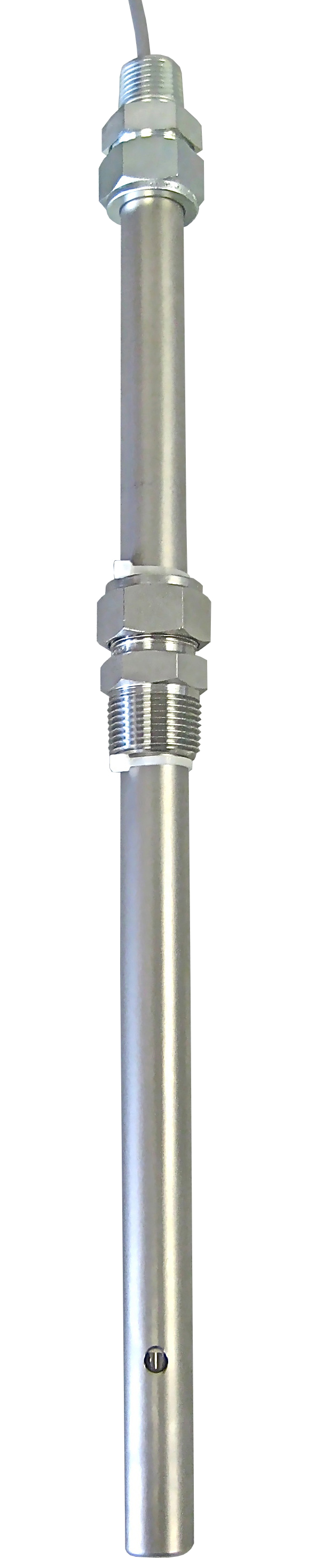

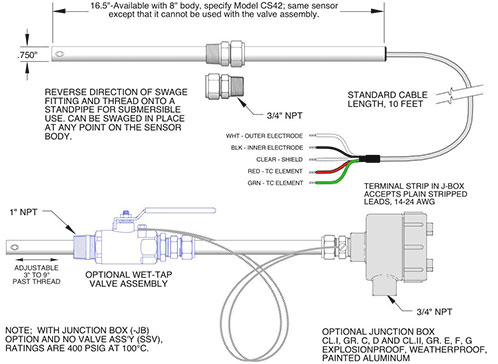

CS40 & CS42 Conductivity Sensors

- Measure conductivity directly in process temperatures up to 150ºC @ 100 PSIG

- O-ring seals used on all versions for high on-stream reliability

- Optional wet-tap valve allows insertion and removal with line under pressure

The CS40 and CS42 sensors have been designed for a wide measurement range in difficult process conditions. It can be installed in submersion, insertion, or wet-tap configurations, and is good for most applications from high purity water to high chemical concentrations.

Application Notes

Wetted materials of construction are 316 stainless steel and PEEK, with alternate materials available on request. All possible leak paths through the sensor are double sealed with EPDM O-rings for maximum on-stream reliability. The front O-rings isolate the back ones from chemical attack, giving more than double the service life that can be expected from single sealed units. Process connections are made via a bored through swage fitting with 3/4″ NPT threads. This fitting can be screwed into a line, a tank, or the optional wet-tap valve assembly. It can also be turned around and connected to a standpipe for use in a submersion configuration. Available cell constants range from 0.01 to 20.0 giving it a very broad scope of application.

TEMPERATURE COMPENSATION:

Available options include Pt1000, Pt100, 3K BALCO, 8,55K NTC, Ni100 and many others. Reference the make and model of instrument for assistance in selecting the right element.

SPECIFICATIONS

MAX. PRESSURE/TEMP. RATINGS:

100 PSIG at 150ºC

Valve Assembly – 50 PSIG at all temperatures, no exceptions.

WETTED MATERIALS:

Insulator – PEEK

O-Rings – EPDM FDA APPROVED

Electrodes – 316 Stainless Steel

CONNECTIONS:

Process – 3/4” NPT, 1″ NPT for valve

Electrical – 3/4” FNPT conduit hub; terminal

strip to accept stripped leads, 14-24 ga.

CELL CONSTANTS:

20 / 10 / 5 / 2 / 1 / 0.2 / 0.1 / 0.05 / 0.02 / 0.01