Conductivity

Properly understood and applied, conductivity is probably simpler to operate and maintain than any other analytical measurement. Each type of sensor has certain applications for which it is best suited. Most applications decisions involve the sensor more than the instrument. Modern instruments are so featured-packed that they will cover almost any application, but not so the sensors. They are where the measurement system meets the process.

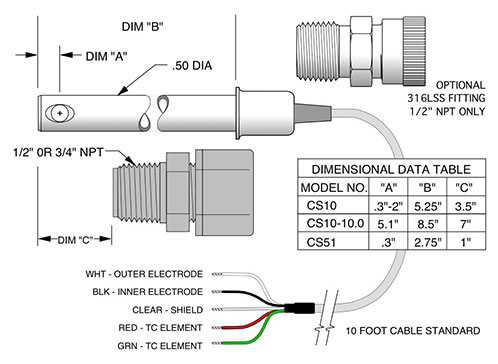

CS10 & CS51 Conductivity Sensors

- Small size enables convenient installation and service

- O-ring seals used on all versions for high on-stream reliability

- Plastic gland fitting allows removal and replacement without tools

The CS10 and CS51 sensors offer a compact design that allows installation into standard pipe fittings in small line sizes such as 3/4″ and 1”, avoiding the need for special flow cells. Simplicity of the design also allows them to be economically offered in exotic metals for especially corrosive chemical applications.

Application Notes

Wetted materials of construction are 316 stainless steel and Teflon, with double o-ring seals at all points. The outer EPDM o-ring bears the brunt of process interface, allowing the back o-ring to maintain reliable sealing free from chemical attack. An integral temperature element tailored to the analyzer of choice allows automatic compensation for maximum accuracy. Leads are 10′ standard, stripped and tinned ends or optional spade lugs. Process connections are made via a bored through polypro fitting with 1/2″ or 3/4″ NPT threads. This fitting can be screwed into a line, or tank, and it can also be turned around and connected to a standpipe for use in a submersion configuration. The CS51 is good for general purpose use up to about 10,000 microsiemens or higher on most analyzers, while the CS10 covers a broader range of cell constants and therefore of conductivities.

TEMPERATURE COMPENSATION:

Available options include Pt1000, Pt100, 3K

BALCO, 8,55K NTC, Ni100 and many others.

Reference the make and model of instrument for assistance in selecting the right element.

SPECIFICATIONS

MAX. PRESSURE/TEMP. RATINGS:

100 PSIG at 100ºC w/POLYPRO

150 PSIG at 120ºC w/Kynar

200 PSIG at 120ºC w/316SS FITTING

500 PSIG at 100ºC w/316SS FITTING

WETTED MATERIALS:

Insulator – Teflon

O-Rings – EPDM FDA APPROVED

Metals – 316LSS Standard; Monel, Titanium

and Hastelloy C-276 optional.

Fitting – Polypropylene Standard, 316LSS

and Kynar optional.

CONNECTIONS:

Polypropylene Process Fitting – 1/2″ or 3/4″ NPT

Stainless Steel Process Fitting – 1/2″ NPT

Kynar Process Fitting – 1/2″ NPT

Electrical – 24 gauge stripped and tinned ends

CELL CONSTANTS:

CS10 – 10.0 / 1.0 / 0.2 / 0.1 / 0.05 / 0.02 / 0.01

CS51 – 1.0 / 0.2 / 0.1